Why can’t we all be more like the Danes?

Posted in Policy, Repowering communities on 07/29/2010 04:47 pm by In many ways Denmark acts as a natural test-bed for many of the technologies needed to control climate change. It has pursued pro-CHP policies for over twenty-five years and pro-renewable policies for the past 15 years.

In many ways Denmark acts as a natural test-bed for many of the technologies needed to control climate change. It has pursued pro-CHP policies for over twenty-five years and pro-renewable policies for the past 15 years.

As a result Denmark is close to the theoretical limit for CHP penetration:

- It has expanded its district heating network to 50,000km – about 40% of heat demand is now supplied through district heating as opposed to individual boilers.

- It has increased the share of combined heat and power – 82% of heat in the district heating systems is CHP. Top-up boilers are used to supply heat in the coldest months. By 2005, about 97% of thermal power capacity (non wind-power) was CHP. CHP generation accounted for 63.2% of thermal electricity generation. This difference between 97% and 63% reflects the lack of demand for heat in summer, so plant capable of CHP is run in power only mode.

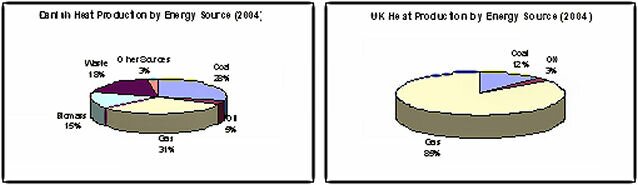

- It has expanded the amount of renewables and waste used in CHP to decarbonise the heat – in 2002 waste and biomass accounted for 36% of fuel inputs used for heating. CHP from waste is a particular feature of heat production, accounting for 18% of inputs. Heavy use is still made of coal – even in relatively urban areas.

Fuel mix for heating 2004

IEA Energy Statistics 2004; available at International Energy Agency.

Denmark is now close to fully exploiting CHP, with nearly all its thermal power stations linked to district heating networks. They have hit upon two limits which restrict further extension. Firstly, seasonality of heat demand – demand in August is about a sixth of December demand. This means that the average utilisation for CHP across the year is much lower than the theoretical 95%. The second issue is that the per capita winter demand for heat is much greater than the amount of waste heat generated by per capita electricity demand. As a result, at the national level, some of the winter heat will always have to be supplied from non-CHP plants. Therefore, it is not economic to extend the heat network to the entire population. Danes have pragmatically introduced it to urban locations, regulating that all buildings connect with a few pragmatic exceptions.

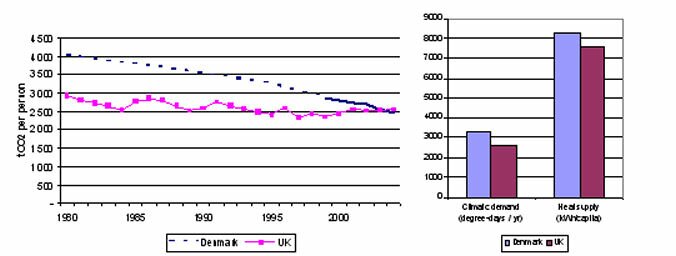

Roll-out of CHP in Denmark has contributed to reductions in residential heat emissions

Denmark has reduced its CO2 emissions from heating by almost 40% between 1980 and 2004; in the same period UK emissions dropped by 13%. The Danish fuel mix has become less carbon intensive, the use of coal has declined by about 40% and that of gas and renewables increased correspondingly. The UK has also had experienced a similar switch from coal to gas for its domestic sector energy use– albeit from a lower base. Denmark’s per capita emissions have now fallen slightly below than the UK’s, despite its colder climate. This reflects the penetration of CHP and renewables.

Domestic sector emissions of carbon dioxide, relative demand for heating

Source: Calculations based on data from Defra, Danish Energy Authority; Danish data adjusted for climate variation and net exports of electricity; Climatic demand based on isotherm maps produced by Ecoheat and Cool project, supported by Intelligent energy EU Commission.

Prices paid for heat vary across Denmark and are difficult to compare with UK gas price but appear broadly similar or slightly higher than UK prices

Denmark has invested substantial sums in developing its heat network. These have included costs of constructing the heat network (these are quoted as averaging £1000/m), of installing heat meters and heat exchangers (which cost approximately £200 and £800 to buy, plus installation costs). The heat infrastructure once developed has long life times – heat pipes inspected 50 years after their initial construction are still regarded as fully functional. The heat meters need to be replaced every seven years.

The variable cost of the supplying the heat varies between locations and is hard to compare in a straightforward fashion with UK prices. Within Denmark, district heating is 30% cheaper than heating with individual boilers. However, the figures are likely to overstate the true cost differential since individual boilers are used in less densely populated areas, pushing up average costs. In Copenhagen (where residents pay close to the average price), the heat transmitter VEKS sells its heat to the municipal distribution companies for £25/MWh – similar to the UK retail price of gas before VAT. This price includes the substantial service charge VEKS pays on its debts (about two thirds of the price) and payments to the heat suppliers, but excludes the costs of Denmark’s energy taxes. VEKS has made major investments in establishing its heat transmission infrastructure. Between 1986 and 1991 it built 104 km of heat mains, 44 heat exchangers and pumping stations at the cost of £230 million (its annual turnover is £100 million). This money was borrowed from financial institutions but backed by the Danish government. Consumers are also spared the cost of purchasing and maintaining the boiler. The heat exchanger is a simpler and cheaper heating system.

The heat price quoted above do not include for the price that heat was ultimately sold to consumers (once the local municipality has added its margin) nor the losses of heat in the local distribution system – roughly 10 to 15%. This suggests that DH fuel costs in Copenhagen are currently slightly higher than UK, reflecting the current high debt service costs. Heat is bought from CHP or waste at the marginal incremental cost of producing the heat. This means that CHP and waste will always be despatched in preference to heat only boiler.

How did Denmark get there?

Following the oil shock of the 1970s Danes pursued policies to diversify away from oil to other fuels, including coal and gas

In 1979, as a result of the oil shocks of the 1970s, the Danes introduced the Heat Law. Municipalities were asked to identify all their local heat sources (waste incinerators, power plants, refineries) and heat loads in order that the supply of heat could be centrally organised. The heat sector is a planned monopoly, in the sense, that areas of space are designated as either gas heated or district heated according to the housing density.

… Environmental considerations entered the thinking after 1990

Since 1990, Danish policy became more focussed on reducing CO2 emissions and the decision was taken to convert the district heating plant to CHP. Between 1990 and 1994, many large coal and gas fired DH systems were converted to gas-CHP. Between 1994 and 1998, the remainder of smaller DH systems near the gas network were converted to CHP. DH systems away from the gas network are progressively being converted to straw and biomass. Decentralised heat production, in heat only boilers, has been replaced by large centralised CHP plant where possible often using renewable energy sources.

Incentives to encourage the investment and operation of CHP and renewables

Denmark has numerous policies to encourage the uptake of CHP. The most important are carbon/energy taxes, which raise about £4bn and are levied on electricity, CO2 and fuel inputs. There are also regulatory policies, but these are backstop policies essentially mandating companies and households to follow-through measures that fiscal and subsidy policy has already made economically rational, for example, bans on electrical resistance heating, compulsory connection to DH systems (exemptions apply where costs of connection are disproportionate). The price received for electricity sales from CHP have three elements:

- A time related tariff – set a little over market prices.

- Additional sweeteners for decentralised CHP plants of lessn than 25MWe.

- Supplements for Energy from Waste (£10/MWh) and biomass (approx £17/MWh) – both are guaranteed this support for 6 to 15 years.

Biogas, wood chip and straw is guaranteed a price of about £60/MWh for up to 20 years. Heat is always sold to the heat network at the long-run marginal cost of production, that is, to reflect the fuel, investment and a fair return on capital.

The Copenhagen system

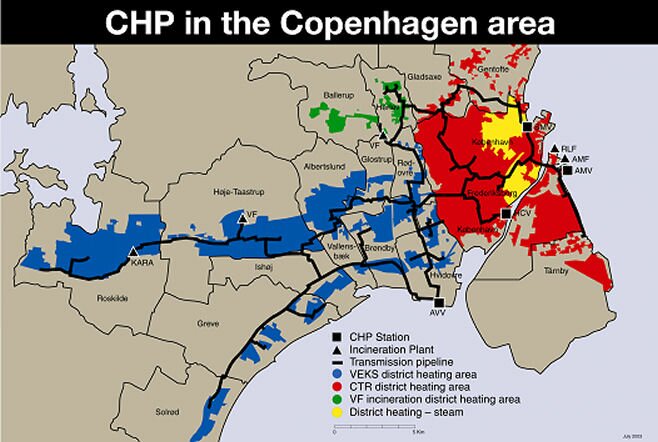

The CHP is most developed in Copenhagen. The development of the district heating network commenced in the 1920s. The main elements are the heat producers, a “high capacity” heat transmissions system that takes heat from the large central heat producers to the localities and the local heat distribution system. VEKS and CTR, the two transmission companies, have 104 km of pipe which transmits heat up to 40km. Transmission losses are 2%. A local heat distribution system owned by the municipalities transmits the heat the last few kilometers from the transmission system to homes. Losses here are higher at about 15%. The diagram below shows the heat transmission network in Copenhagen; the rectangles and triangles indicate the location of the CHP and heat only plant. They range in size from community scale plants such as the 60MWe Kara waste CHP plant, and large centralised power plant like the state-of-the-art flexibly fired CHP plant – like Avedore (840MWe).

The combustion of waste and biomass provides about a third of the thermal energy, fossil fuels provide the remaining two-thirds. Around 40% of the waste produced by Copenhagen is incinerated, over 50% is recycled and around 3% is landfilled. Further decarbonisation will require replacing the fossil fuels with biomass. The largest municipal energy company within greater Copenhagen is Cogenhagen Energy (kobenhavns E) which was first set up in 1857. As well as electricity and hot water, it also supplies town gas for cooking, water and sewerage services. It is replacing coal with wood in two of its CHP plants. The system is largely state owned with a mixture of co-operative and municipal ownership. However, heat plant, heat transmission and heat distribution are managed and operated as separate financial entities and prices are set to reflect the full economic cost of each stage.

District heating can be competitive

In 2009 the district heating price was 45% of the price of oil heating and 56% of natural gas prices.

Heat metering is now the norm within Denmark.

However, in 1995 50% of homes did not have heat metering. Consumption dropped by 15% from introducing the metering, consistent with figures reported in other countries. Within apartment blocks Danes make use of cheap (£5 per radiator) evaporation meters which are used to share out the buildings properly metered heat demand between tenants.

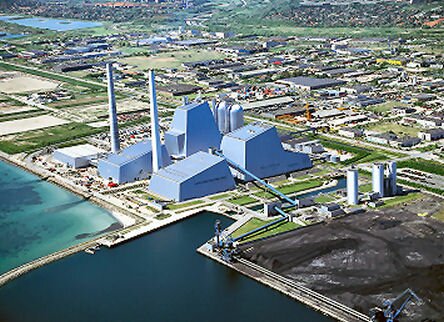

Large new flexibly fuelled powered CHP plant like Avedore can produce competitive electricity and heating

Avedore is a large 840MWe flexibly fuelled CHP plant that combusts a range of fuels – the bracketed numbers give approximate fuel use in 2006: coal (500t), straw (160t), wood pellet (100t), gas (135m m3)and oil (260,000t). It consists of two generators Avedore 1 built in 1991, AV2 in 2001. Heat is stored on site for up ten hours, in vast heat tanks. It has a theoretical maximum thermal efficiency of 95%, but the seasonality of the heat demand meant the plant always produced much less marketable heat than this.

Avedore is a large 840MWe flexibly fuelled CHP plant that combusts a range of fuels – the bracketed numbers give approximate fuel use in 2006: coal (500t), straw (160t), wood pellet (100t), gas (135m m3)and oil (260,000t). It consists of two generators Avedore 1 built in 1991, AV2 in 2001. Heat is stored on site for up ten hours, in vast heat tanks. It has a theoretical maximum thermal efficiency of 95%, but the seasonality of the heat demand meant the plant always produced much less marketable heat than this.

It provides power for 1.2 million people and heat for 300,000. Heat is transmitted to Copenhagen approximately 30km away by a heat pipeline owned by VEKS. Heat is sent at 110°C and returned at 50°C. The local heat distribution companies like Copenhagen Energy are responsible for the legacy local district heating networks and customer handling. Heat losses in the district network are 16 to 17%, in low density housing this rises to 20 to 25%.

Copenhagen is experimenting with district cooling in the heart of its central business district, and geothermal

A small district cooling system has been planned to connect 16 commercial buildings in the heart of the old city. The 2km of pipe is expected to cost £2.3m. The technology is expected to be highly carbon efficient saving 80% of the electricity of air conditioning and 1200 tCO2/year. It uses a mixture of sea-water and heat pump powered chiller units to produce cooling water.

Some challenges

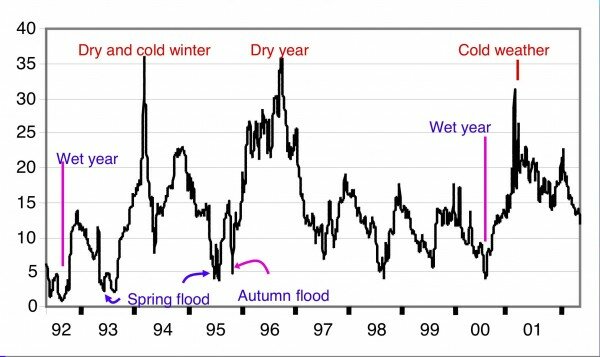

Danish energy policy, like that of other European countries, is requiring the liberalisation and unbundling of the different stages of power production (generation, transmission and distribution). This exposes the system planners to the volatile power prices in the Nordpool (which covers Scandinavia). These change dramatically as a result of temperature and climate effecting the output from hydro (wet/dry years) and wind (windy/wind-free days). This makes the scheduling and operation of the heat and power outputs from the CHP system more complex. Copenhagen Energy works with the two transmission companies in greater Copenhagen VEKS and CTR to ensure that revenues are maximised.

System Price of power in Nord Pool – 7-day rolling average (€c/kWh)

Another challenge for Copenhagen is improving the quality of insulation in its older pipelines and replacing the steam pipes in some of the older parts of the city with newer water based systems. These are in the heart of the city and very expensive to excavate.

Questions:

- Denmark passed the Heat law requiring households to connect to district heating networks and dramatically improving the economics and financiability of retrofit DH programmes. Have any other countries contemplated the same?

- The cost of creating or extending new DH networks is regarded as prohibitive by many countries. Have any nations integrated such investment with other network renewal programmes, for example, fibre optic/water.

- What are the costs of metering heat?